Wet blasting, sometimes referred to as vapor blasting is the process for removing a coating layer (e.g. paint, rust, dirt) from a surface, or preparing a surface for recoating using pressurised water and abrasive blast media.

WET BLASTING IN THE AEROSPACE INDUSTRY

One big advantage of wet blasting is that it enables the user to control the blasting process and this is especially important when dealing with high-precision manufacturing applications often used in the aerospace industry.

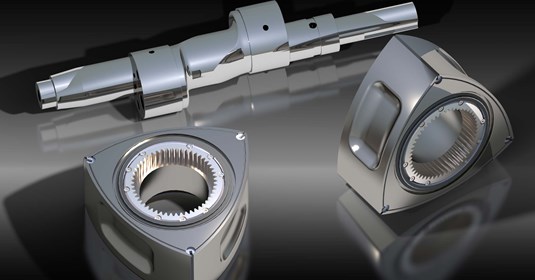

Wet blasting can be used for surface preparation during the manufacturing or repairing various aircraft parts and components, including engine turbines and landing gear equipment.

Another reason why it is commonly used in the aerospace industry is its ability to produce a consistent finish on surfaces. Components used in the aviation and aerospace sector are required to meet extremely high standards and wet blasting helps to ensure these standards are met time after time.

WET BEAD BLASTING

Contact our team of experts to discuss the benefits of wet bead blasting.

Our team are happy to answer any questions you have about using our products and services in your next project. Fill in your details below and we'll be in touch.