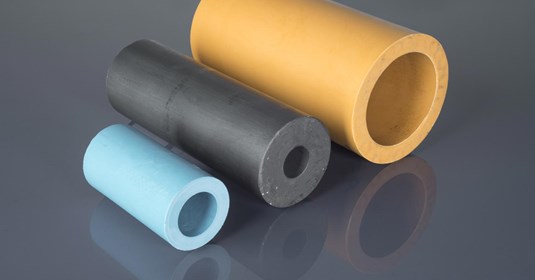

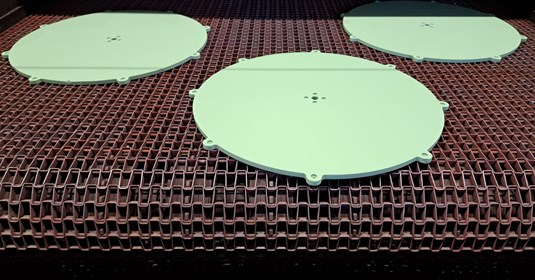

The most common fluoropolymer application is in process valves. We provide valve seats, manufactured from our AF range of materials, including PTFE and filled PTFE, VICTREX PEEK and filled PEEK materials, PEEK HT, Vespel®, PCTFE, Nylon and Acetal.

Products Include

- Seats and seat inserts

- Thrust washers and backup rings

- Stem packings

- High-performance spring energised body seat and stem seals

-

PTFE

Being hydrophobic, non-wetting, high density and resistant to high temperatures, PTFE is an incredibly versatile material with a wide variety of applications, though it's perhaps best-known for its non-stick properties.

-

VICTREX PEEK

It is a linear, aromatic, semi-crystalline polymer widely regarded as one of the highest performing thermoplastics in the world. It provides a unique combination and range of high performance properties.

Make use of our team to create the valve seats that are right for your project

We've been working with clients across the world to create valve seats and other precision plastic components for many years. Our team can advise you on the best choice of material for your application and even help design a bespoke material for you.

Valve Seat Material SELECTION

We have a broad range of valve seat materials to suit your application, have a look at the table below or call us on 01992 515880 to talk to us in more depth about your project.

You can also find individual datasheets in our Materials Section.

| Material Name | Main Properties | Notes | Temperature Range |

|---|---|---|---|

| VIRGIN PTFE | Very low coefficient of friction and excellent chemical resistance. | FDA approved | -40°C to 260°C |

| 15% Glass Filled PTFE | Decreased compressive strength and lower deformation under load than virgin PTFE. | Abrasive material | -40°C to 260°C |

| 25% Glass Filled PTFE | Similar to 15% Glass better wear resistance, higher compressive strength and lower deformation under load. | Abrasive material | -40°C to 260°C |

| Stainless Steel Filled PTFE | Extremely hard wearing. Excellent strength and stability under extreme loads and elevated temperatures. | Can be used on steam and thermal fluid applications | -40°C to 260°C |

| TFM | Much denser polymer structure than Virgin PTFE. Displays better stress recovery. | Modified TFE Polymer | -40°C to 260°C |

| Carbon Graphite filled TFM | Lower thermal expansion-contraction rate than conventional TFM. | Ideal for use on steam and thermal fluid applications | -40°C to 260°C and even 320°C on Thermal Fluid applications |

| UHMWPE | Highly resistant to corrosive chemicals, with the exception of oxidising acids and organic solvents. | Also known as High Modulus Polyethylene (HMPE) or High Performance Polyethylene (HPPE) | -40°C to +80°C |

| PCTFE | Excellent for cryogenic and Oxygen use. | A homo-polymer of Chlorotrifluoroethylene | -270°C to 260°C |

| Virgin PEEK 450G | Excellent chemical resistance and mechanical properties at elevated temperatures. | An organic polymer thermoplastic | -40°C to 260°C |

| Carbon Filled PEEK | Many similar properties to Virgin PEEK. Particularly suitable for elevated temperatures and high load situations. | Low coefficient of friction and suitable for many extremely corrosive applications | -40°C to 260°C |

| PEEK HT | Retains all key features and benefits of PEEK 450G but retains physical properties to a higher temperature. | Can be supplied in both virgin unfilled or as filled compounded material | up to 260°C |

| Acetal and Delrin | Displays good resistance to wear and deformation under load. | Excellent for valve seat applications | up to 80°C |

| VESPEL | A polyimide material that has high temperature capabilities under load and is mainly used for heat transfer applications, hot gases and oils. | Must not be used with STEAM |

Valve Seats

Contact us to discuss our valve seats services.

Our team are happy to answer any questions you have about using our products and services in your next project. Fill in your details below and we'll be in touch.