AFT Fluorotec have provided solutions for those restoring classic vehicles for years.

Restoring any classic vehicle requires a huge amount of time and effort, not to mention funds. Therefore, it is understandable that classic car restorers want to ensure they can maintain the pleasure they get from their classic vehicles for as long as possible.

However, Classic vehicles rust

There is still the underlying problem that old vehicles rust quickly, even if it has been beautifully restored. Rusting is accelerated by the salt used to keep roads safe in winter. Classic vehicles often rust to pieces long before they fail mechanically.

What is rust?

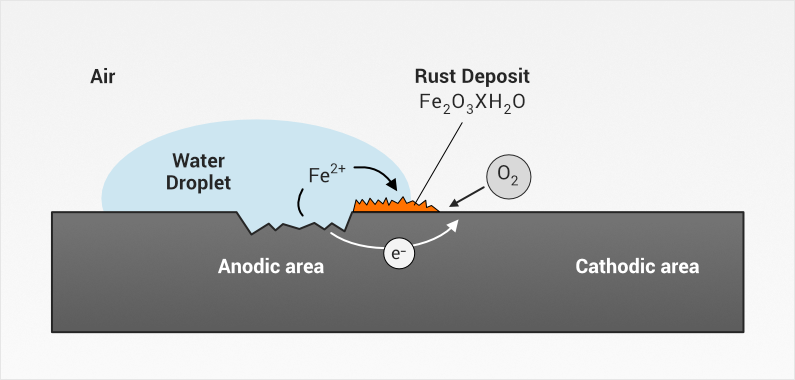

Rust is a type of corrosion. Rusting occurs when a ‘galvanic’ cell exists. This causes the degradation of the metal surface and the production of unwanted rust deposits.

Why do modern cars not rust like they used to?

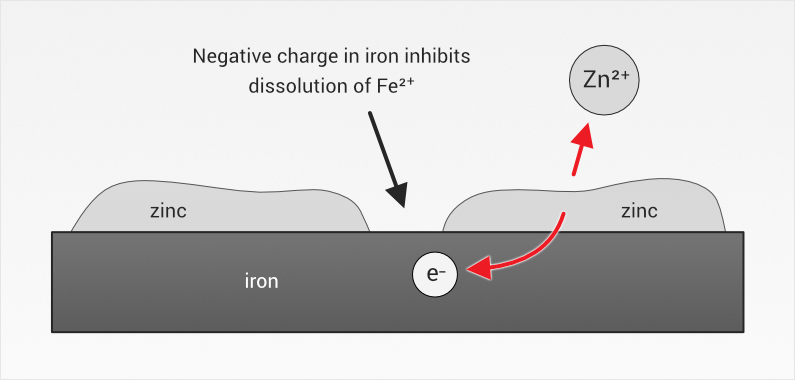

The harsh road conditions for cars has not changed but modern cars do not rust in the same way as the classic cars do. The steel that modern cars are made from is coated with a thin layer of zinc (galvanizing) at the steel making facility. These zinc coated sheets of steel are then pressed into the body panels, subframes or chassis of the modern car.

The zinc acts as a protective barrier for the steel. Even when this barrier is breached, it still protects the steel by corroding first. This is known as sacrificial corrosion. The zinc therefore enables the steel to function for many years without succumbing to rusting.

The diagram below shows how zinc provides sacrificial corrosion protection and prevents rust.

Our thermally sprayed zinc is an ideal way to ensure your restored vehicle stays 'rust-free'

Our thermally sprayed zinc provides restored classic vehicles with a long ‘rust-free’ life that modern vehicles have. This prevents the classic car enthusiast's pride and joy from quickly returning to the rusty condition they were in before restoration.

For years AFT Fluorotec have provided sacrificial rust protective solutions to our customers who restore classic vehicles, by means of our thermally sprayed zinc. The thermally sprayed zinc enables the parts and panels of the restored classic vehicle to exhibit the long rust-free life that modern cars show.

Our care and understanding for your classic treasure

All classic car restoration enthusiasts know that great care is required when handling the delicate parts and body panels of a classic vehicle during the restoration process. Our years of expertise and experience in this area ensures that your parts are not distorted or damaged during the surface preparation and thermally sprayed zinc processes.

Commitment to quality

We understand that excellent surface preparation is essential to ensure maximum performance from our coatings. No matter how good the liquid or thermally sprayed zinc coating is, it will not perform to its full capabilities on a poorly prepared surface.

The surface preparation process

For vehicle restoration, the removal of an existing coating, cleaning the surface and preparing it for the coating is essential. We control our processes, such as blasting, in such a way that the surfaces of the classic vehicle parts and panels are prepared without damage or distortion.

We ensure all surfaces to be coated are clean from oil and other debris, which could cause contamination. Controlled blasting of the surface increases the surface area of the part ensuring good adhesion of the thermally applied zinc without the distortions that you get with processes such as hot dip galvanising.